Frequently Asked Questions

Contents

- What are your delivery charges?

- Do you class my address as Scottish Highlands?

- I live outside the UK. How can I buy without paying UK VAT?

- I ordered plans and instructions as a PDF download. How do I download them?

- How green (eco-friendly) are the boats?

- Will I complete the boat in the stated build time?

- Do the plans contain full-size drawings?

- Are the offsets always positive?

- When making the joints the panel does not have the correct offset. Have the parts been cut wrongly?

- The joints moved after I glued them but before it set. Do I need a new set of panels?

- Should I worry that the wood made a splitting sound when I moved it?

- Can I get replacement panels?

- I am running out of epoxy. Can I purchase some more?

- When I wire it together the panels do not fit. Can I get a replacement kit?

- Have I got the wrong bulkheads since they do not fit?

- How large a gap can I fill with epoxy?

- How safe is it to use epoxy resin?

- Can I use the epoxy in cold weather?

- How much overhang is allowed when transporting a boat on a car roof rack?

- What is LapStitch™?

If your question is not answered on this page, please contact us directly so we may answer it. You can also find or ask for advice from fellow boat builders on our boat-building forum. For our boat-building courses, please see our Courses FAQ.

What are your delivery charges?

Delivery charges are calculated based on the combined size and weight of all items in your order. When you have added all items to your basket, proceed to the checkout and simply select a delivery area from the drop-down menu to find out the precise delivery charge for your order, including options for delivery speeds where available.

Approximate delivery charges are also listed on our delivery charges page, to give you a rough idea.

Do you class my address as Scottish Highlands?

Different couriers specify different areas for their Highlands surcharges. Currently, we send most UK kit orders by DX, who simply apply the surcharge to the Highland Council area. If you are still unsure, please get in touch before ordering or put the order through as Highlands and add a note to the order asking us to check this. Since we don't store card details, it is easier for us to refund the difference than to take an additional payment.

Of course, you can always avoid the surcharge by collecting your order from us in the Lake District or by having it delivered to a friend living outside the Highlands area. Please get in touch to check the box sizes before deciding whether you can transport it.

I live outside the UK. How can I buy without paying UK VAT?

The prices on our website include UK VAT but this will automatically be deducted when you select your country at the checkout.

I ordered plans and instructions as a PDF download. How do I download them?

If you have ordered PDF downloads, you will automatically be sent an email containing the download link, shortly after your order is confirmed. This is separate from the order confirmation email. If it isn't in your inbox, please check your spam or junk folder. Please get in touch with us if you still haven't received it after a few hours.

How green (eco-friendly) are the boats?

The marine plywood we use is from Forestry Stewardship Council (FSC) approved sources and produced in Lloyd's Approved mills. The epoxy we provide does not require solvents. With an expected life of 50 years before they need replacing, our boats are very eco-friendly.

Will I complete the boat in the stated build time?

The build times stated on our website are only an indication, for comparison of different boats. It is the minimum time we believe it is possible for the boat hull to be built, but not finished, by an ordinary person already familiar with the techniques involved. It excludes the time spent waiting for epoxy to cure or admiring your progress over a cup of tea.

It is not sensible for most people to attempt to build the boat in this time: the build should not be treated as a job or it will become a chore. Spending a couple of hours per evening, with a few more at the weekend, is the best way to approach the build. We know of people who built Skiffs in three days and others who spread the work over a couple of years.

Do the plans contain full-size drawings?

Some of the plans comprise only full size drawings; others either have lofting points for the panels or lofting points for the larger panels and full size drawings for some of the smaller panels. Unless otherwise stated in the description, the plans do not contain complete full-size drawings. Many consider that lofting is an easier way of making more accurately cut panels. Instructions for lofting are given in most of the manuals and we will give advice as required.

Are the offsets always positive?

No, sometimes the offset is negative – that is, below the datum line. It is also not uncommon for a single panel to have both negative and positive offsets. The draughtsman does not draw the plans like this or calculate the offset like this but to save space in the shed when assembling one of our boats we move the datum line close to the panel which means that positives and negatives can occur.

When making the joints the panel does not have the correct offset. Have the parts been cut wrongly?

It is unlikely that the panels have been cut to the wrong shape. In building a boat of this nature even a 6mm discrepancy between the stated offset and the panel would not be critical as far at the finished product is concerned. The panels are accurately cut and should be correct: the builder should check everything but the plans engender a spurious accuracy. Get everything as close as possible, however, do not panic if it is not achievable and don't waste too much time on the last couple of millimetres. The differences lie with the flexibility of the wood. It is possible that it was not packed flat but more likely that it has taken on a bend whilst it has been resting. This is nothing to worry about.

To reassure yourself clamp the ends of the panels to the bench. Then, holding the joint together, slide the middle of the wood in the horizontal plane. When the panel is glued up you are very likely to be able to move it by at least 25mm. Once the panel is offered up to the other panels and it bends in the other dimension it becomes even more flexible and 25 mm can easily be ironed out (don't try this just let the panel fall to the correct place as you wire up).

The joints moved after I glued them but before it set. Do I need a new set of panels?

Great care should be exercised when gluing to ensure that the panels do not move when the clamps are applied. Do not walk away without checking but it is often difficult to check if the joint is covered with a piece of scrap wood to avoid damage to the ply. The best way to check is to have traced the outline of the panel on the floor or the bench and ensure that it has not moved. However, it is highly unlikely that the joint will have moved so far as to necessitate a new set of panels (see the previous answer for reassurance). The main problem is that additional work is now necessary.

The gap in the joint will have to be carefully filled and sanded smooth without damaging the veneers more than necessary. If there has been a large slip the tips of the panel may be too close to the datum line and have to be trimmed but do not do so until the panel has been tied in place since it is unlikely to be required. The joint is likely to be strong enough but whilst the panel is being moved about it would be as well to protect it by sandwiching it between some scrap plywood and holding the scrap in place with a couple of spring clamps. There will be no problem once the panel is attached to the boat.

Should I worry that the wood made a splitting sound when I moved it?

Yes. Long panels are delicate before they form the boat. Do not move them more than necessary or pick them up in the middle. Enlist someone else to help when moving the panels if possible. Rotate the panels so that the thin edge is at the top and the face is vertical before moving them.

Can I get replacement panels?

Fyne Boat Kits can supply replacement panels but more often than not there are ways of avoiding the expense. Please telephone the workshop for advice.

I am running out of epoxy. Can I purchase some more?

Supplying additional epoxy is a lucrative business but Fyne Boat Kits are slightly reluctant to do so. The kit comes with more than enough epoxy providing care is taken and it is not wasted. It is very difficult to assess how much epoxy is needed to complete a boat particularly since the final few processes are coating the wood which, out of necessity, require very little epoxy. Thickly applied epoxy adds weight to the boat and lightens the wallet, it also increases the amount of sanding needed. When mixing epoxy one should always have a few additional jobs, such as hole filling, to use up any remaining epoxy rather than throw it away.

If required Fyne Boat Kits can supply more epoxy. If it is ordered in the morning of a working day it will usually be delivered in the UK on the following working day. Thus it can be ordered only when you are certain that you have not got sufficient.

When I wire it together the panels do not fit. Can I get a replacement kit?

The kit will go together although it may not seem likely at the beginning. The trick is to wire the panels together very loosely so that they can be slid backwards and forwards. Only when the entire boat is wired up and the panels slid about to obtain a good fit should the ties be hand tightened. Most of the boats should be built on two trestles or saw horses (or similar) and not on a flat surface. A flat surface cause gaps to open since it prevents a rocker developing.

Have I got the wrong bulkheads since they do not fit?

All wood bends differently and it is not unusual for bulkheads not to fit precisely where they should. With some pulling and pushing of the panels they will fit but most people simply move the bulkhead a little until it does fit. Sloping the bulkhead so that the top is slightly nearer than the bottom to the closest end of the boat often helps and also looks attractive. It is important not to locate the bulkhead so far from the end of the boat that the tank top or seat does not reach it.

How large a gap can I fill with epoxy?

A gap of up to 25 mm can be filled with thickened epoxy, but it is not good practice to have large filled holes in a boat since it adds weight.

How safe is it to use epoxy resin?

Although the epoxy we supply is a modern solvent free epoxy it is still possible to become sensitised to the epoxy components. Sensitivity usually manifests itself as a type of dermatitis with red sores appearing on forearms, wrists and hands. To avoid sensitisation, we strongly recommend you take safety precautions when using epoxy. Please contact us if you require further advice or clarification.

Can I use the epoxy in cold weather?

Yes, as long as the epoxy is warm. Building in unheated sheds is not unusual but the epoxy should be kept off a cold concrete floor or, better still, be placed over a gentle heat. When the job is finished for the day the bottles should be put in a box and placed in a warm place such as a boiler room or an airing cupboard. If it is very cold, rather than heating the entire shed one should heat the wood with a gentle heat source.

If the epoxy resin gets cold it will become viscous and, eventually, crystallize. The problem with this is that it cannot easily be dispensed and is rather difficult to mix. The resin can be brought back to a usable state by warming the bottles and contents but this can take several hours which many will find frustrating if they have gone out to the shed to work for an hour. The best method of warming the epoxy components is by plunging the bottles into hot water.

How much overhang is allowed when transporting a boat on a car roof rack?

The rules vary by country, so please check before travelling.

In the UK, the end of the boat must be made clearly visible if it overhangs the rear of the vehicle by more than a metre (e.g. by hanging something flourescent/reflective from the end). The boat can overhang the front and rear of the vehicle by up to two metres without additional requirements. It can also overhang either side of the vehicle by up to 305 mm.

More details are available from the UK government website.

Please note that it is up to you to make sure the load is safe and secure. You must also ensure that the combined weight of your boat and roof rack is within the roof weight limit for your car.

What is LapStitch™?

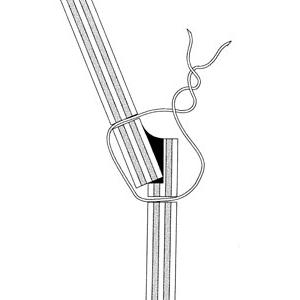

Cross-sectional diagram of LapStitch construction

CLC'S exclusive LapStitch™ construction, Patent No. 6,142,093.

The strength of the LapStitch™ joint is such that the designs require comparatively little fibreglass or fillet work, making them especially easy to build. Our system combines the unquestioned grace of lapstrake or clinker hulls with the proven ease of stitch-and-glue construction.

Lapstrake hull shapes evolved over millennia. Many would suggest that the type reached a high water mark with the Viking longboats, but the actual building method was little changed right up into the 20th century. Planks were nailed or riveted together, and the technique required prodigious skill on the part of boat builders.

Over the last 30 years, the advent of modern adhesives and high quality marine plywoods brought about the first major innovation in lapstrake building methods: glued plywood lapstrake hulls. This method of planking produces very strong, stiff, and beautiful hulls that never leak. This is progress, to be sure, but glued lapstrake boats still require moulds and arcane joinery skills. It isn't a process suited to amateurs.

Nesting Eastport Pram rowing and sailing dinghy with LapStitch construction

In 1997, Chesapeake Light Craft developed a way to build lapstrake boats without moulds or complex ‘rolling bevels’ on the lapstrake planking. Using sophisticated computer design software, we are now able to devise hull shapes that will assume a round-bottomed shape without a jig or ‘torturing’ of the wood. A special groove is machined into each panel so that they are self-aligning. They are wired together just like a stitch-and-glue kayak. When these joints are filled with epoxy, the result is a remarkably stiff and strong hull that has the appearance of traditional lapstrake or clinker planking.