Types of Joints Used for Wooden Boat Building

There are three usual ways of joining plywood panels together: butt joints, scarf joints and puzzle joints. The pre-cut joints in our kits are either of the scarf or puzzle type.

Butt Joint

For a butt joint, the edges of the wood are pressed together and a backing block affixed over the joint.

The backing block is usually made from scrap plywood which makes the joint thick and unsightly. This backing block makes the wood rigid so that it does not take on a smooth curve when the panels are bent to form the side of the boat. The glued surface of the joint is relatively short and the joint relies on the backing for its strength rather than the epoxy. However, this type of joint is easy to make.

Because of the limitations of butt joints, almost none of our kits use these.

Scarf Joint

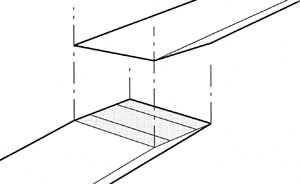

Scarf joint

For a scarf joint, the edges of the panel are chamfered to a slope. The slope on one panel is the opposite of that on the other so that the two panels can fit together.

The slope on both side of the joint has to be the same thus this is not an easy joint to make. When assembling, aligning the two pieces of plywood is tricky and the panels are prone to move before the glue is set. When made correctly there is only a thin joining glue line visible even though the point of contact between the pieces of wood is relatively large and provides great strength. The joint is as strong and flexible as the surrounding wood and so bends in a fair curve with no ugly backing piece to spoil the line of the boat.

Puzzle Joint

Puzzle joint

In certain circumstances a puzzle joint can be used without compromising the strength of the vessel.

The joint, which has a large gluing area, is as strong as the scarf joint except where it is on the curve of the hull. As long as there is not an excessive bend, the joint is very strong. The joints are easy to assemble but not everyone finds them attractive (at least to start with). The major advantage of this joint is that there is no need for a string line to get the panels correctly aligned.